ALDEX Strong Base Anion Series

SB-1P OH SC Strong Base Anion Exchange Resin – Hydroxide Form

Aldex SB-1P OH SC is a high purity, narrow particle size distribution type 1 strong base anion exchange resin recommended for use in single vessels, working mixed beds and / or polishing mixed beds. Aldex SB-1P OH SC is a very light colored, highly regenerated semi-conductor grade resin that is often used with Aldex C800H SC (LS) in high purity mixed beds.

Download Aldex SB-1P OH SC Technical Bulletin (PDF)

Physical Chemical Properties

| Polymer Structure: | Gellular polystyrene - divinylbenzene matrix |

| Ionic Form as Shipped: | OH- |

| Functional Group: | Quaternary Ammonium, Type 1 |

| Physical Form: | Spherical beads |

| Moisture Content: | 55 to 65% |

| Uniformity Coefficient: | 1.4 maximum |

| Reversible Swelling, Cl- to OH-: | 20% maximum |

| Conversion to OH Form: | ≥ 95% |

| Conversion to Cl Form: | ≤ 0.5% |

| Conversion to CO3 Form: | < 5.0% |

| Conversion to SO4 Form: | ≤ 0.1% |

| Shipping Weight: | 40 to 42 lbs per cubic foot |

| Total Capacity OH- Form: | 1.0 eq/l (21.8 Kgr/ft3) |

| Specific Gravity: | 1.07 |

Recommended Operating Conditions

| Maximum Temperature: Cl- Form OH- Form | 212°F 140°F |

SB-1P OH SC Features

Very Low Color, Taste or Odor

Aldex SB-1P OH SC meets the requirements for paragraph 173.25 of the Food Additive Regulation of the U.S. Food and Drug Administration.

Long Life

Strong and durable beads insure long service life.

Reliability

Aldex Chemical has over 34 years of field usage by thousands of customers demonstrating the reliability of Aldex ion exchange resins, zeolites, and other water treatment media.

Applications

Demineralization; suitable for whole bead or powdered resin usage.

Safety Information

A material safety data sheet is available for Aldex SB-1P OH SC. Copies can be obtained from Aldex Chemical Co., LTD. Aldex SB-1P OH SC is not a hazardous product and is not WHMIS controlled.

Caution: Acidic and basic regenerant solutions are corrosive and should be handled in a manner that will prevent eye and skin contact. Before using strong oxidizing agents in contact with ion exchange resin, consult sources knowledgeable in the handling of these materials.

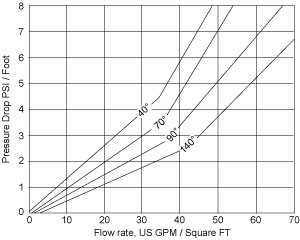

Pressure Drop

Fig. 1 shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures.

Fig. 1 Pressure Drop vs Flow Rate at various degrees Fahrenheit (F°)

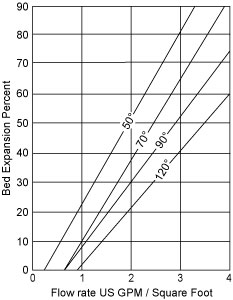

Backwash Characteristics

After each cycle the resin bed should be backwashed at a rate that expands the bed 50 to 75 percent. This will remove any foreign matter and reclassify the bed. Fig. 2 shows the expansion characteristics of Aldex SB-1P OH SC in the chloride form.

Fig. 2 Bed Expansion vs Flow Rate at various degrees Fahrenheit (F°)

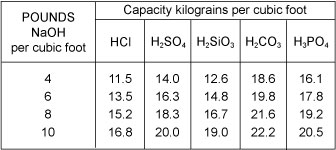

Operating Capacity

Fig. 3 shows operating capacity of Aldex SB-1P OH SC for acid removal at various regeneration levels when treating an influent with a concentration of 500 ppm, as CaCO3.

Fig. 3 Operating Capacity

Applications

Demineralizations

Aldex SB-1P OH SC is widely used in multiple and mixed bed demineralizers, wherever complete ion and organic removal are required. The porosity of Aldex SB-1P OH SC provides the capability of reversibly sorbing naturally occurring organic substances that tend to foul anion resins.

Type 1 anion exchanges have greater thermal and oxidation resistance than other types of stong base resins and can be operated at higher temperature to insure low silica leakages. The combination of porosity and functionality make SB-1P OH SC the resin of choice where the water temperature is in excess of 85°F or where the combination of carbon dioxide plus silica exceed 40% of the total anions.

The low density of Aldex SB-1P OH SC provides maximum separation during the regeneration cycle of mixed bed demineralizers. This results in longer service runs and higher quality effluents.

Desilicizers

In certain applications, water supplied with low dissolved solids need only be treated for hardness and silica removal. Aldex C-800 operating in the sodium cycle followed by Aldex SP-1P OH SC operated in the hydroxide cycle is a very effective way of providing low silica, and low hardness water for medium pressure boilers.