ALDEX Mixed Bed Resin

MB-2 (SC) High Purity Mixed Bed using Type 2 Anion

Aldex MB-2 (SC) is a highly regenerated mixed bed of Type 2 strong base, gel anion exchange resin and a strong acid cation exchange resin, designed to provide ultra-high purity water. It can provide as much as 20 percent more throughput capacity than older style mixed beds while maintaining effluent purity levels in excess of 15 megohms. The special blend of Type 2 anion exchange resin with nuclear grade cation exchange resin ensures high effluent resistivity, low TOC extractables and excellent regenerable capacities for inorganic versus organic ions. It is recommended for all polishing demineralizer applications where high sensitivity, low silica water is required and is especially well-suited for cartridge applications.

Aldex MB-2 (SC) Technical Bulletin: English (PDF)

Aldex MB-2 (SC) Safety Data Sheets: English (PDF) | Français (PDF)

Physical Chemical Properties

| Polymer Structure: Cation Anion | Hydrogen form sulfonated polystyrene copolymer Hydroxyl form strong base alkyl quaternary ammonium polystyrene copolymer |

| Ionic Form as Shipped: | Hydrogen / Hydroxide |

| Physical Form: | Spherical beads |

| Particle Size Distribution: 16 mesh (U.S. Std.) -40 mesh | 2% maximum 2% maximum |

| pH Range: | 0 to 14 |

| Moisture Content: | 60% maximum |

| Conversion to ionic Form: Cation - Hydrogen Anion - Hydroxide Chloride (Cl-) Carbonate (CO3-2) Sulfate (SO4) | 99% minimum 95% minimum 0.5% maximum 2% maximum 0.1% maximum |

| Shipping Weight: | 45 lbs per cubic foot |

| Total Capacity: Cation (H+ form) Anion (Cl- form) | 1.8 meq/ml 1.2 meq/ml |

Recommended Operating Conditions

| Effluent Quality: | Resin should provide effluent quality of 15 to 17 megohm but is dependent on many factors |

| Maximum Temperature: Regenerable Non-regenerable | 40°C 60°C |

| Slow Rinse (Displacement) Flow Rate: | 2 to 10 US GPM per cubic foot |

MB-2 (SC) Features

Very Low Metal Content

Special manufacturing conditions ensure very low metal content.

Elemental analysis, dry basis

| Iron (Fe) | <100 ppm |

| Copper (Cu) | <50 ppm |

| Lead (Pb) | <50 ppm |

Very Low TOC

Nonsolvent sulfonation and special manufacturing processes assure very low TOC leakage.

Uniform Particle Size

98% of all beads are in the minus 16 to plus 40 mesh range: giving a lower pressure drop while maintaining the superior kinetics of standard mesh size products.

Superior Physical Stability

90% plus sphericity and high crush strengths together with a very uniform particle size provide greater resistance to bead breakage while maintaining low pressure drop.

Safety Information

A material safety data sheet is available for Aldex MB-2 (SC). Copies can be obtained from Aldex Chemical Co., LTD. Aldex MB-2 (SC) is not a hazardous product and is not WHMIS controlled.

Caution: Acidic and basic regenerant solutions are corrosive and should be handled in a manner that will prevent eye and skin contact. Before using strong oxidizing agents in contact with ion exchange resin, consult sources knowledgeable in the handling of these materials.

These suggestions and data are based on information we believe to be reliable. They are offered in good faith. However, we do not make any guarantee or warranty. We caution against using these products in an unsafe manner or in violation of any patents. Further, we assume no liability for the consequences of such actions.

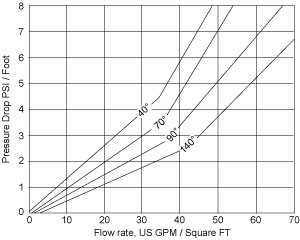

Pressure Drop

Fig. 1 shows the expected pressure loss per foot of bed depth as a function of flow rate at various temperatures.

Fig. 1 Pressure Drop vs Flow Rate at various degrees Fahrenheit (F°)

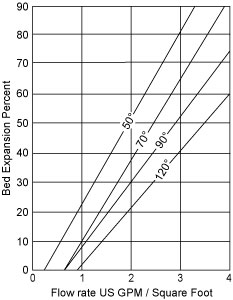

Backwash Characteristics

After each cycle the resin bed should be backwashed at a rate that expands the bed 50 to 75 percent. This will remove any foreign matter and reclassify the bed. Fig. 2 shows the expansion characteristics of Aldex MB-2 (SC) in the chloride form.

Fig. 2 Bed Expansion vs Flow Rate at various degrees Fahrenheit (F°)